Thermal Analysis

31 January, 2016

As part of our condition monitoring service, CBC Technical Services provides a thermal analysis program which includes thermography and digital temperature recording. Thermal analysis can reveal problems in a vast range of mechanical and electrical applications precisely, quickly and effectively.

As part of our condition monitoring service, CBC Technical Services provides a thermal analysis program which includes thermography and digital temperature recording. Thermal analysis can reveal problems in a vast range of mechanical and electrical applications precisely, quickly and effectively.

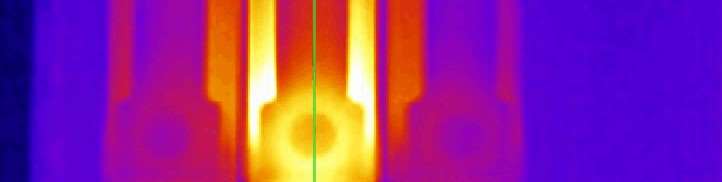

Thermography uses cameras to measure infrared radiation, creating thermal images of equipment which show variations in temperature as brightly coloured patterns, providing crucial information for many applications, including:Electrical (high & low

voltage systems): Loose/over tight connections, overloaded components, uneven

voltage distribution, failed/fatigued components and dead battery cells.

Mechanical: Condition of

bearings, shaft misalignment, faulty electrical connections, plumbing leaks and

blockages, defective seals and valves, storage tank levels, furnace tube

coking, settlement and sludge build up, baseline temperature readings during commissioning

of plant equipment and refractory surveys – inspection for loose or missing

refractory lining in boilers, furnaces, reactors and similar high temperature

vessels.

Digital temperature

recording is a stand alone time and temperature tracker in a stainless steel

button, which is affixed to equipment to record temperature at regular,

adjustable intervals. Data is downloaded to specialised software for analysis

of results.

Thermal measurement and

analysis programs make information accessible without having to make contact

with equipment, creating a safer workplace. They can assist in identifying

potential failures or inefficiencies in time to prevent loss of production,

breakdown of equipment or fire hazards. Their use is virtually unlimited; detecting

the presence of heat or even cold anywhere can help in making a determination

of equipment performance condition.

Used in conjunction with

CBC’s vibration analysis and/or oil sampling programs, these highly effective

plant awareness programs can improve plant up-time and reduce the cost of not

knowing.