Installation Guide - Fenner Flex Tyre Coupling

Author - Steve Hittmann CBC Power Transmission Product Manager

Installation of a Flexible Shaft Tyre Coupling - Fenner Flex Tyre Coupling

CBC’s range of Martin Flex and Fenner Flex tyre couplings provide all the desirable features one requires when looking for a flexible shaft connection. Both Martin Flex and Fenner Flex tyre couplings come with the convenience of Taper Bush mounting for fixing to the shaft. The tyre coupling is a “torsionally elastic” coupling that gives designers, engineers, and maintenance personnel the versatility needed to meet many applications found within the industry today.

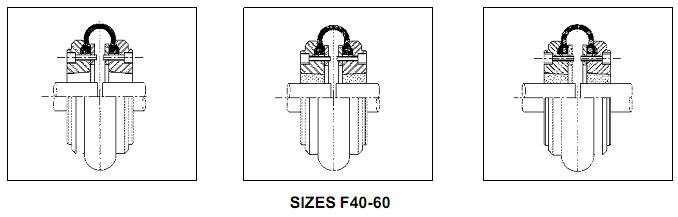

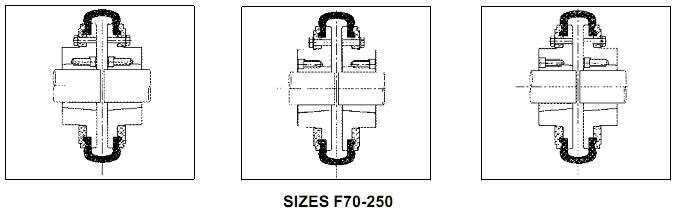

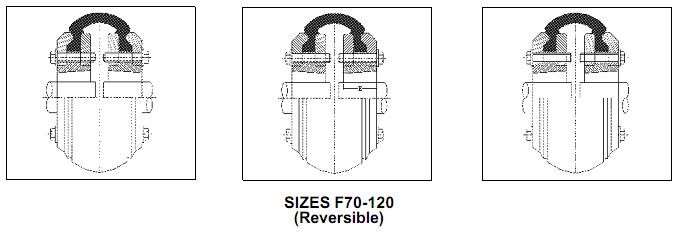

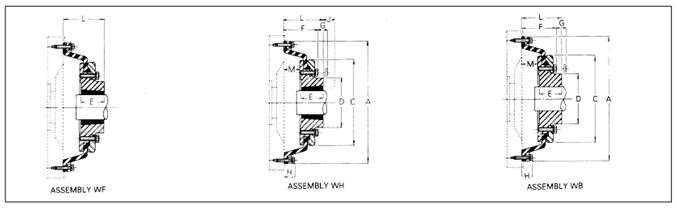

The variety of different flange arrangements, in either F (Face) or H (Hub) flange, allows the Taper Lock Bush to enter the hub from inside the coupling (F Flange). This allows the tyre coupling hub to be mounted against the bearing on a shaft, which will reduce overhung loads. Or the Taper Lock Bush is able to enter the hub from outside the coupling (H Flange), which, in some applications, may assist with ease of installation. Please see pictorial configurations below.

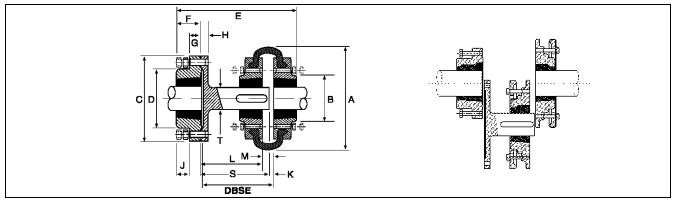

A feature offered by the Martin-Flex and Fenner Flex tyre couplings, which are not commonly available from other manufacturers, is the addition of a spacer unit accommodating for standard distances between shaft ends (DBSE). This often facilitates ease of maintenance for pump applications of 100, 140, & 180 mm DBSE. For further details, please refer to Figure 1 below.

Figure 1

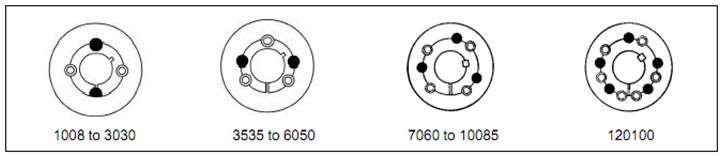

A further design option offered by both the Martin-Flex and Fenner Flex tyre couplings, again not provided by other manufacturers, is the addition of a fly wheel unit, which is designed to accommodate standard SAE flywheel designs and many other original equipment designs for combustion engines. These flywheel couplings use chloroprene flexible elements and employ standard F and H type driving flanges, as pictured below in Figure 2.

Figure 2

The tyre coupling offers excellent shock absorbing properties, reducing vibration by up to 30%. It can also accommodate simultaneous misalignment in all planes, without imposing any undue loads on adjacent bearings. The natural rubber element can be used in ambient temperatures between -50 degrees Celsius and +50 degrees Celsius. Also available from CBC, and now the industry standard, is a Chloroprene Rubber element with an allowable temperature range from -15 degrees Celsius to +75 degrees Celsius. This element meets the requirements of the Australian Fire Resistant Anti Static (FRAS) standards, set for rubber products that are designed to be used in flame proof environments. In addition to this safety factor, this material also has excellent resistance to contaminated environments including oil and grease.

Installation of a Tyre Coupling

Installation of a tyre coupling, including Martin Flex and Fenner Flex tyre couplings is as follows.

- The Taper Bush should be cleaned to remove any grease, oil or contaminants. The shaft and the bore of the tyre coupling hub, into which the taper bush is to be installed, also needs to be cleaned of oil, grease, dirt, or metal filings.

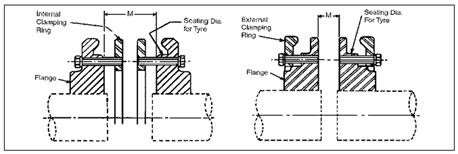

- It is a good idea to check both the bushing and the tyre coupling are free of nicks and burrs, and are not showing signs of cracking or damage. Place the taper bush in the tyre coupling hub, ensuring half holes are matched to make complete holes, taking note to match holes, and not threads. Each complete hole must be threaded on one side only.

- To facilitate ease of fitment, all threads should be oiled, as well as the point of the set screws or threads. Under the head of the cap screw should also be well oiled. Place the screws, but do not tighten, into the holes of the tyre coupling hub with threads on the hub side. Shown as in Figure 3 below.

| Method | Accuracy |

| By eye | This is a very rough and inaccurate method of

alignment. It does not allow for issues such as thermal expansion. |

| 6 inch rule | This is better than ‘by eye’. This method has a

low degree of accuracy, and should only be used in an emergency and on small (<7.5 kW) drives. |

| Taper gauge | A low degree of accuracy, this method assumes

that the faces of the coupling are parallel to the shaft and to each other. |

| Rim and face, Single dial, Reverse dial | Often requires custom brackets and equipment and

requires very experienced personnel. This method also assumes the couplings are machined concentric and square. When correctly applied, this method can be very accurate, but time consuming. Bar sag is a factor of rim and face alignment methodology, which is an influencing factor that is, unfortunately, not often accounted for. |

| Laser | This method is fast and offers the most accurate

alignment. Some laser alignment devices have become so user friendly that minimal knowledge and training is required to operate them to achieve accurate alignment. |

The Martin-Flex or Fenner Flex tyre coupling is a versatile option for connecting shafts, offering excellent vibration absorption, misalignment capability, and cost effectiveness. Alternative makers of tyre couplings available from CBC include Rathi, Tyreflex, Optiflex, Rexnord Omega Coupling, and Viva Coupling. CBC Power Transmission technical personnel require the following basic criteria to undertake a selection.

- Application details

- Input power

- Speed (RPH)

- Shaft sizes

- Distance between shaft ends

- Duty cycle (stop/starts etc)

- Operating environment

Selection via these criteria ensures the demands of the application may be met with the most suitable, cost effective and maintenance-friendly option.

There are many alternative tyre coupling designs available from the CBC range, including HRC Couplings, Grid couplings, gear couplings, disc couplings, and flywheel couplings. Each offers a varying range of advantages and disadvantages. Selecting the correct tyre coupling for the application is critical for achieving a maximum design life.