Elges Maintenance Free Spherical Plain Bearing

Author - Sam Houston Regional Manager SA/NT

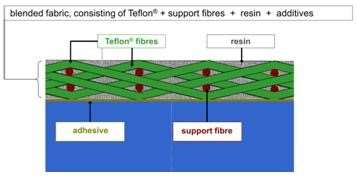

The Scaeffler Group (INA/FAG) have invested considerable research and development into incorporating PTFE (Teflon®) technology into their range of Elges maintenance free spherical plain bearings.

CBC stock this range as our premuim performance bearing option for suitable designs due to the high load capacity and moisture absorbtion resistance.

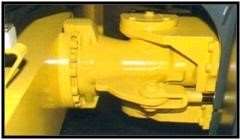

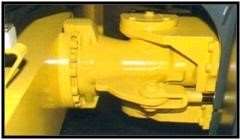

Spherical plain bearings are ready-to-fit, standardised machine components which are suitable for slow tilting and swivel motion. Rod ends of hydraulic cylinders, articulated steering systems in heavy trucks, ladles in steel plants are some of the many applications featuring this operating condition.

Spherical plain bearings are ready-to-fit, standardised machine components which are suitable for slow tilting and swivel motion. Rod ends of hydraulic cylinders, articulated steering systems in heavy trucks, ladles in steel plants are some of the many applications featuring this operating condition.

The ability to compensate angular misalignment makes spherical plain bearings also an ideal choice for applications in civil engineering. Here welded steel structures and/or concrete structures require a higher ability to compensate misalignment over and above what rolling bearing options can offer. Changes in ambient temperature, wind force or even earthquakes can also lead to distortion of civil engineering structures. Spherical plain bearings are ideal to deal with these operating conditions. Some examples are bascule bridges, sport arenas, hydro power dams, solar dishes and troughs.

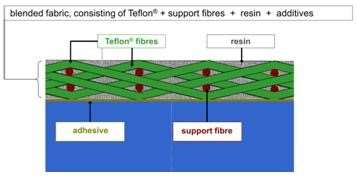

Initial bearing designs for these applications were based on steel outer and inner rings. They required regular relubrication. State-of-the-art designs feature a maintenance-free design sliding contact surface based on Teflon® technology. Teflon® is also known as PTFE (Polytetrafluoroethylene).

Elges maintenance-free spherical plain bearings contain a layer of ELGOGLIDE® in the bore of the outer ring. A cross section of this layer is shown in attached picture.

In principle, Teflon® replaces traditional lubricants such as grease or oil. The layer composition ensures continuous availability of Teflon® over a very long period of time. Thus re-lubrication is not required. This property can be very beneficial when maintenance must be eliminated in inaccessible or hazardous locations (apart from saving maintenance costs and time).

Resistance against humidity is another unique feature of ELGOGLIDE®. Operation in tropical and coastal locations does not affect bonding and behaviour of the material.

The hardened and ground inner ring is hard chromium plated. The smooth contact surface not only contributes to the low coefficient of friction of the bearing. It also provides an excellent surface for the seal lips of the seals.

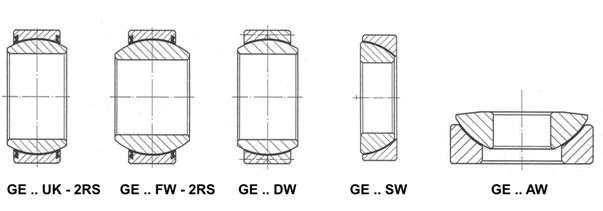

Various bearing series are available, offering the choice between different designs regarding main load direction (radial, angular, axial) and possible tilting angle between inner and outer ring. This allows optimal bearing selection to corresponding operating condition.

Maintenance-free rod end GAR.UK-2RS

Maintenance-free rod end GAR.UK-2RS

Cylindrical bushes are also available. If larger than standard widths are required, two or more bushes can be located next to each other.

Maintenance-free cylindrical bush ZGB

Summary

Elges, ELGOGLIDE® spherical plain bearings are state-of–the-art engineering products which can be integrated in a large variety of machinery. Ultimately higher capacity and lower friction of these bearings offer the operator the benefit of longer operating life, less down time and less maintenance cost compared to other traditional designs.

For further information on maintenance free bearing designs contact your local CBC outlet.

Reference:

Mr Andreas Piper – Schaeffler Group Engineering Manager/Quality Manager

Spherical plain bearings are ready-to-fit, standardised machine components which are suitable for slow tilting and swivel motion. Rod ends of hydraulic cylinders, articulated steering systems in heavy trucks, ladles in steel plants are some of the many applications featuring this operating condition.

Spherical plain bearings are ready-to-fit, standardised machine components which are suitable for slow tilting and swivel motion. Rod ends of hydraulic cylinders, articulated steering systems in heavy trucks, ladles in steel plants are some of the many applications featuring this operating condition.

Maintenance-free rod end GAR.UK-2RS

Maintenance-free rod end GAR.UK-2RS