Article - The Benefits of Using Genuine Wichita Clutch Parts.

Author - Steve Hittmann Power Transmission Product Manager

The Benefits of Using Genuine Wichita Clutch Parts

Author - Steve Hittmann Power Transmission Product Manager

When you consider that the costs associated with down time for a grinding mill on the average mine site exceeds AUD $100,000 per hour, the cost of mechanical components could seem insignificant. Some components, such as the Wichita clutch range supplied by CBC are, in some cases, manufactured to a specific drawing for each particular mill and identified by a serial number. The incidence in the market of copy Wichita clutch parts is becoming more frequent and, considering the issues that have occurred with premature failures and non-compatible matching components, you have to ask yourself, is it worth the risk of using cheaper copy parts?

Some of the common dangers of using non-genuine Wichita clutch components include the following.

- Genuine Wichita airtubes offer four times the life when compared to non-genuine airtubes which can fail prematurely due to insufficient calendar cord wrapping.

- Non-genuine suppliers often provide low quality metal components that are made in China.

- Copy friction discs have been known to be undersized, causing wear in other costly drive components.

- Some Wichita clutch copies promote the use of split airtubes. Whereas Wichita specifies that they are for emergency use only.

- Copy pressure plates have been the subject of early failures and poor performance.

- Non-genuine suppliers often copy to out of date Wichita specifications, due to them having no access to Wichita archives.

- Non-genuine suppliers cannot accurately cross-reference between USA and UK manufactured part numbers, increasing the risk of incorrect parts being supplied.

- On some applications, genuine Wichita friction material lasts up to three times longer than copied parts.

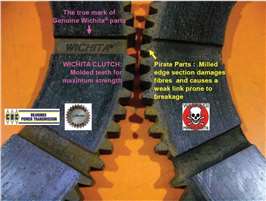

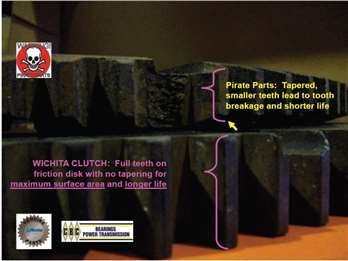

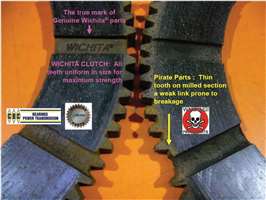

- Genuine Wichita clutch friction discs have high tensile tooth strength, which offers 50% longer life.

- Use of a contaminated grade of copper in copy wear plates results in a significantly shorter working life.

- Non-genuine pressure plates have been subject to catastrophic failure when used at high speed.

- Non-genuine suppliers often use Kevlar friction material, which squeals on high speed applications and is known to fail in high heat applications.

- Wichita UK and Wichita USA are ISO 9001 / ISO 14000 companies.

- Wichita offers a two year warranty.

- Competitors cannot offer genuine Wichita application support.

- The Wichita warranty is invalidated is copy parts are used.

It is easy to see the importance of using genuine Wichita clutch parts. Copy parts may cost less upfront, however, the frequency of occurrence of premature failures and non-compatible matching components can end up costing significant amounts of money in down time and repairs.

To ensure supply of the right parts and correct technical selection of industrial clutch products, contact CBC Power Transmission Technical Specialists. The CBC industrial clutch range includes Wichita clutch, Sprag clutch, Stieber, Eaton Air Flex, and Air Champ indexing clutch.