Article - Chain and Sprocket Wear Gauge For Industrial Roller Chains and Leaf Chains.

Author - Tony Voiklis Power Transmission Specialist

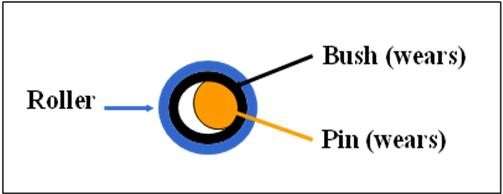

Pin and Bush wear also known as Link Joint Wear – Figure 13.

Proper chain lubrication is essential considerably increasing service life and reducing wear between the chain pin and bush. Lubrication also reduces chain breakages thus reducing “total cost of ownership”. Refer to Section 6 for Chain Lubrication and Diagram Figure 11).

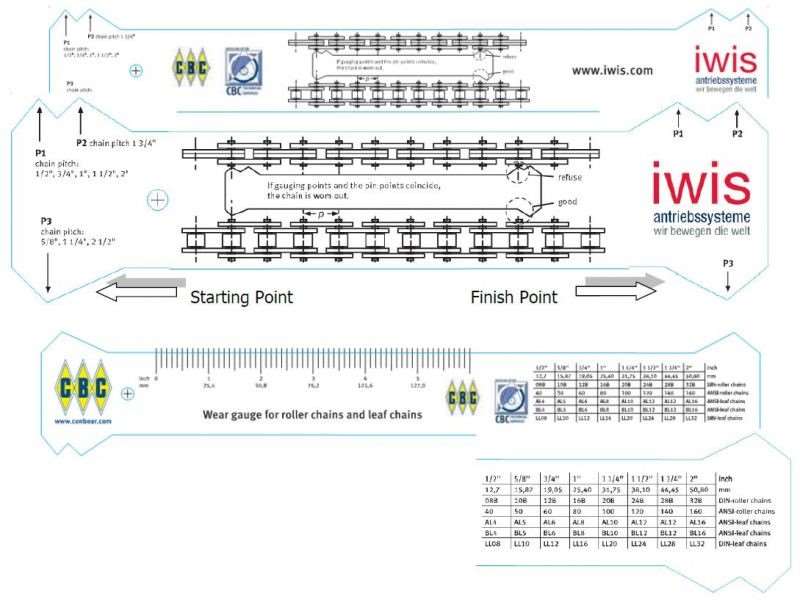

Many industrial chain manufacturers’ and CBC provide an easy to read and use “Wear Gauge Ruler”. This simple tool facilitates measurement checks for excessive chain wear. The chain “Wear Gauge Ruler” can be used on all industrial roller chain and leaf chains. This Wear Gauge Ruler has already considered and includes the 3% elongation formulae measurement for each industrial roller and leaf chains.

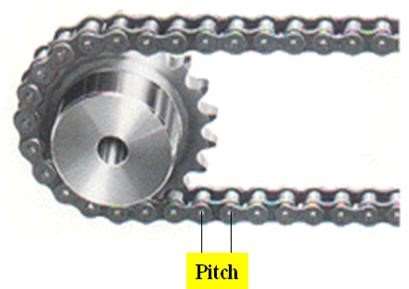

Figure 14.

CBC Chain Wear Gauge Ruler for Industrial Roller and Leaf Chains (Already considered the 3% elongation formulae). – Figure 15.

Simply measure and identify your chain pitch (See diagram Figure 14) and then apply the CBC “Wear Gauge Ruler” over the recommended chain pitches/links for your chain pitch, as given and illustrated on the wear ruler. On this wear gauge ruler there is a starting point and a finish point which is based upon your chain pitch.

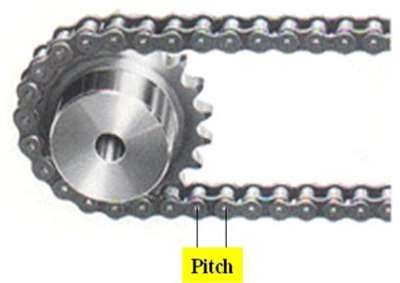

Identify and Measure Chain Pitch (Centre of pins, in inches) – Figure 14.

Industrial Roller and Leaf chains:

- P1 isfor chain pitch ½”, ¾”, 1”, 1 ½”, 2”

- P2 is for chain pitch 1 ¾”

- P3 is for chain pitch 5/8”, 1 ¼”, 2 ½”

Chain must be measured when tight (preloaded). Place the appropriate “P” starting point over one of the chains centre pins and hold the wear ruler in place. Once your adjacent chain centre pin has come in contact with the corresponding illustrated finish “P” point marker, it’s time to replace the chain to prevent any accelerated damage to your sprockets and drive setup. Note:- Your chain has lengthened/elongated and has reached the 3% elongation limit set by manufacturers.

For a short instructional video on how to use the, CBC Chain Wear Gauge Ruler - Click Below:

For a more mathematical method of measuring chain elongation - Refer to Section 10.

You can Click here for further information on “Roller Chain & Sprocket Drives Basic Design Installation & Maintenance”.

Contact CBC for further information regarding any chain performance issue, design or selection issues. Click here for Chain Trouble Shooting Hints and Chain Failures & Causes Chart

The principles above can be applied to any roller chain manufacturer. Some manufacturers undertake varying heat treatment and manufacturing techniques that affect the tensile strength or precision of the chain drive and therefore can provide extended life.

At present ratings, published by IWIS Chain (Germany) makes this brand the premium option considering tensile strength, longevity and performance.

* Warning Safety *

Please turn off the power supply and any other power sources before starting work onto the conveyor or machine/equipment, lock the power sources. Always wear the protective clothes and protective equipment such as safety boots, safety glasses, safety hat, gloves etc.